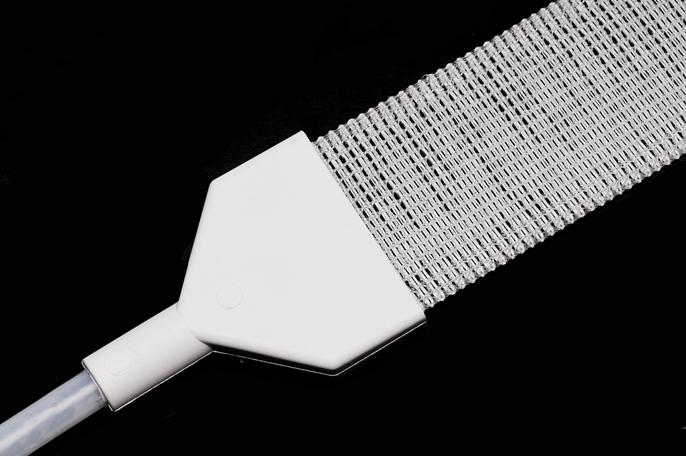

Membrane – VAP® Systems

COMPOSYST has the license from the patent holder AIRBUS Defence and Space GmbH to offer the complete VAP®-portfolio of products and services. Customers can choose from the full range of licensed VAP®-materials developed for manufacturing of high-strength composites. If buyers need further assistance, COMPOSYST can offer experienced experts for consulting.

The Vacuum Assisted Process (VAP®) is a technique to manufacture composite parts using vacuum injection.

Auxiliaries – Consumables

And remember: we don’t just sell these auxiliary materials, we use them in our in-house production — day in, day out. So we are in a position to help you select the products that best match your needs. Get in touch with our team and share your process parameters (resin type, process temperatures, part size and complexity…); we will provide matching auxiliary products and technical support.

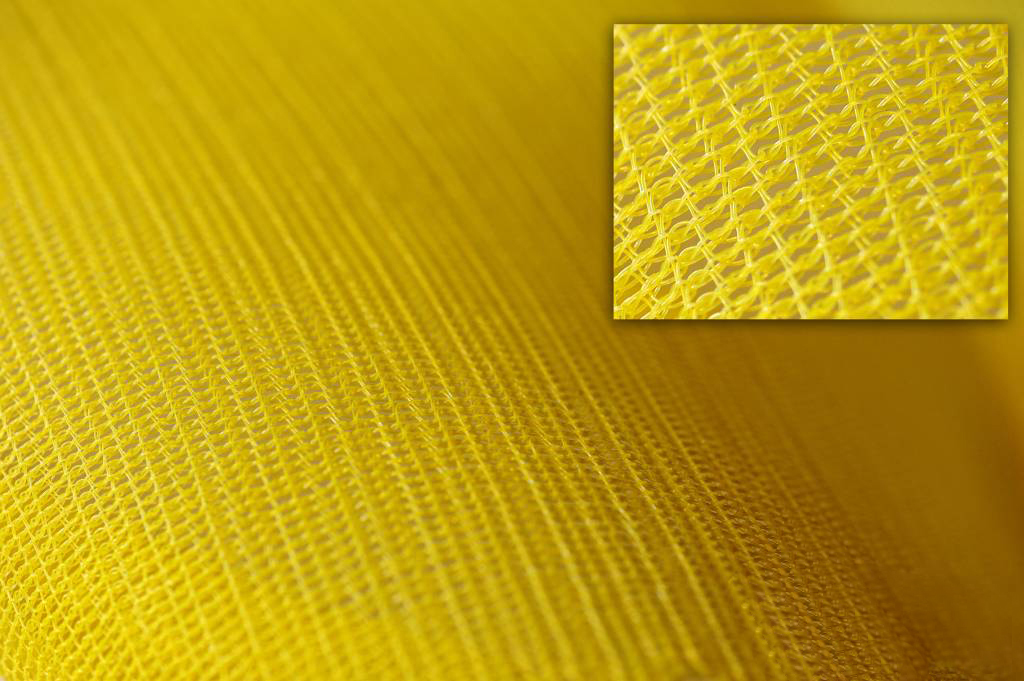

Bleeder / Absorbent Fleece

Flow-/ Vacuummedia

Engineering Services

Profit from decades of experience in the development and manufacturing of composite structures, from prototypes to serial production.

COMPOSYST stands for a lot more than vacuum infusion: we help you choose the right manufacturing process to suit your needs and follow up with our experienced technical support.

Next to our high quality products like lightweight structures or radar absorbing stealth applications for naval systems, we also provide training courses for your employees – either at our facilities or directly at your premises.

COMPOSYST is ISO9001-certified.

- Design Engineering Support

- Concept Development

- Cost Calculation

- Manufacturing Support

- Project Management

- Prototyping

- Small Batch Manufacturing

- Production Engineering

Tools for Infusion Technology

- Development Engineering

- Design

- Project Management

- Production Engineering

- Plastics Technology Fundamentals

- Introduction to Vacuum Infusion

- Customer-Specific Training