Can economy and quality go hand in hand with environmental compatibility?

At COMPOSYST not only the production processes are being continuously optimized, the sustainability factors of our suppliers are also regularly checked and adjusted if necessary.

With our in-house photovoltaic system we already produce 60% of our electricity consumption and at peak times we can even feed the excess into the power grid.

More and more of our products can be made from recycled material – of course with the same quality.

That’s guaranteed.

VAP® CS/E „Recycled”

Our new product VAP® Membrane CS/E “Recycled” is equivalent to the classic VAP® membrane in terms of quality and usability.

Plus, the textile carrier consists of 100% recycled polyester.

The use of recycled polyester reduces the dependency on petroleum as a raw material source, since no new crude oil has to be used for the recycled content.

Depending on the calculation basis, the use of recycled PES can reduce energy consumption by 30 to 60 percent compared to virgin PES.

WRAP estimates that the production of rPET can reduce CO2 emissions by about 30% compared to conventional polyester.

For more WRAP

The use of recycled material greatly reduces the use of chemicals compared to newly manufactured PES.

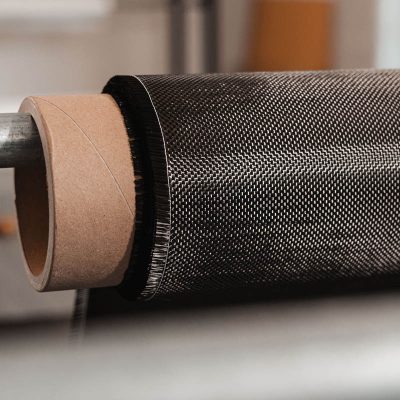

VAP® Process

The process alone – even without recycled auxiliary materials – is more efficient than the autoclave process or prepreg

- Purchasing costs of the autoclave are much higher

- Transport and commissioning of the autoclave result in higher costs and pollute the environment

- High energy costs for the autoclave cycle: Bad for the wallet – and the environment

- Higher (energy) costs for consumables with autoclave process

- Prepregs have to be stored in a freezer

The VAP® process, on the other hand, is simple and inexpensive – but with the highest quality.

- Precise processing of the auxiliary materials

- No wasted resin

- Less post-processing necessary

- Inexpensive consumables

- Use of reycled materials possible

Sustainability factors of the VAP® Membrane CS/E and the infusion process:

Membrane coating with water based formulations without organic solvents – with reduced water consumption and therefore harmless in terms of occupational safety and the environment in production, application and recycling

Short transport routes protect the environment, regional suppliers keep your independence and ensure quality

![]()

ISO 9001 certification, ISO 14001 certification, ISO 45001 certification (via OHRIS PDF in German)

Code of Conduct is based on the internationally recognized principles for the protection of human and labor rights, as set out in the United Nations Universal Declaration of Human Rights, the ILO core labor standards, the UN Guiding Principles on Business and Human Rights and the OECD Guidelines.

ESG

COMPOSYST is aware of its responsibility not only to the environment but also to society.

This results in our active and agile corporate management, which is of course implemented in accordance with ESG guidelines.

We see it as an opportunity to cultivate a positive corporate culture by promoting diversity and inclusion, from which you as a customer can only benefit.