COMPOSYST provides VAP membrane for research

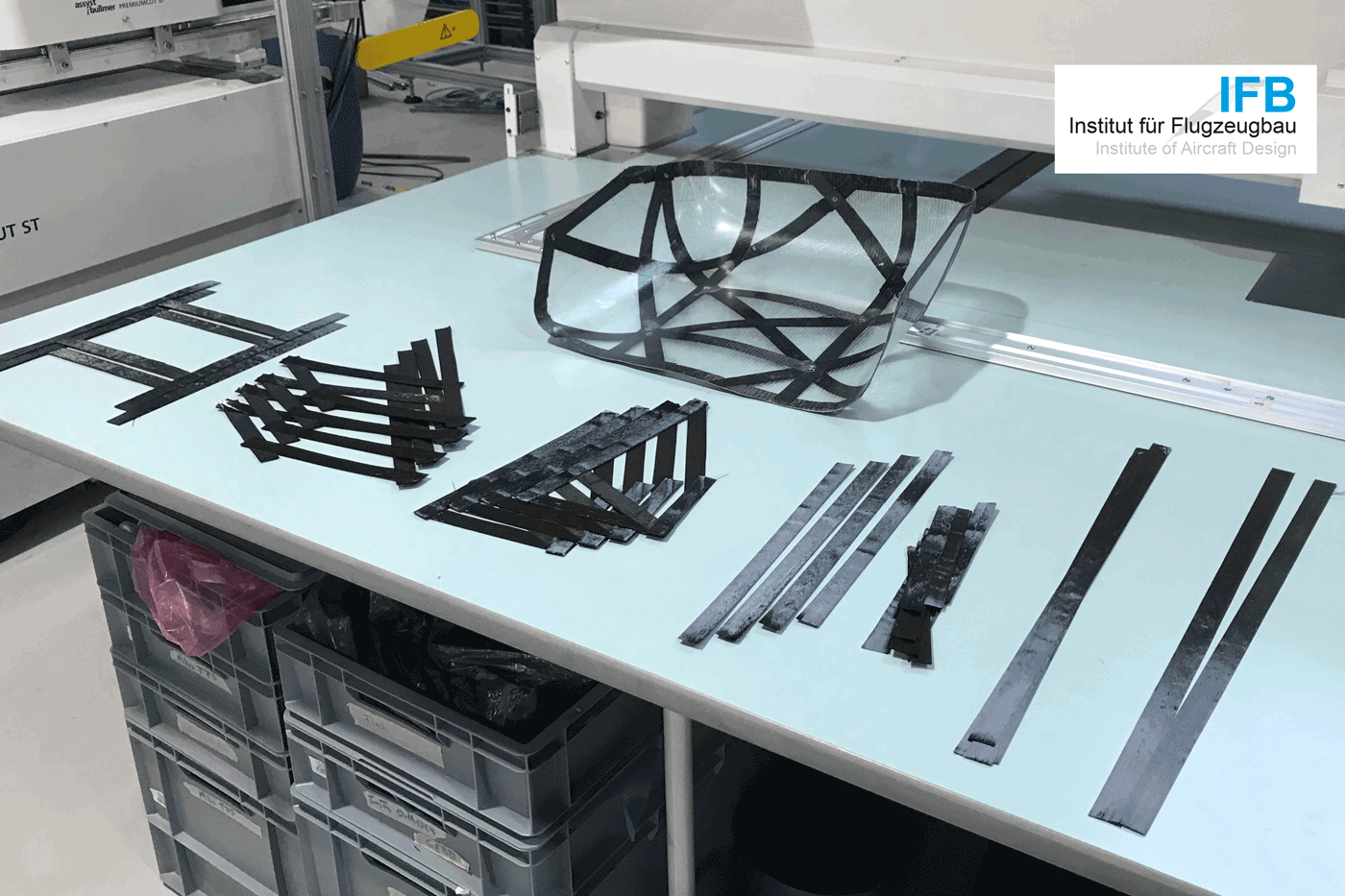

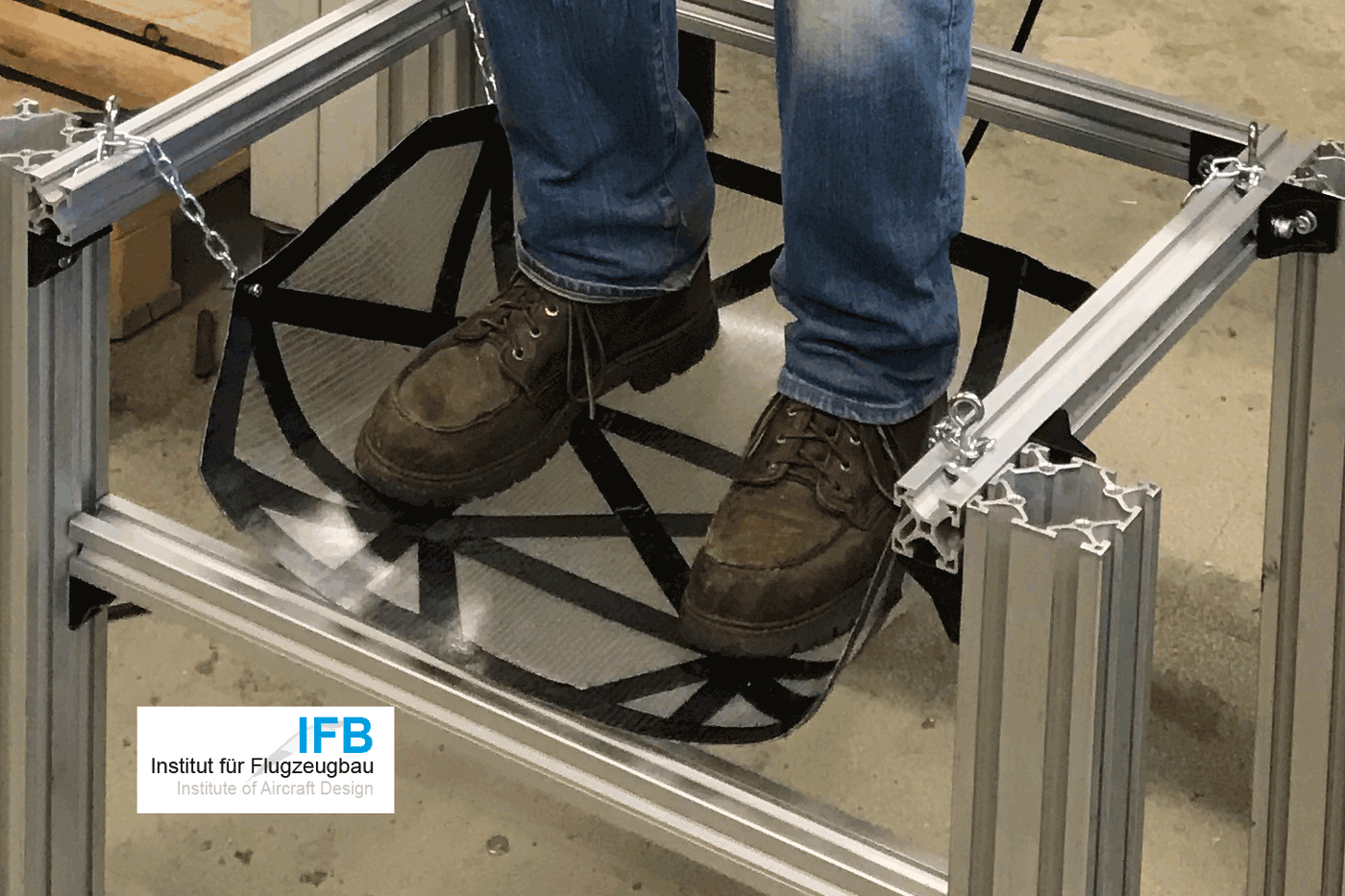

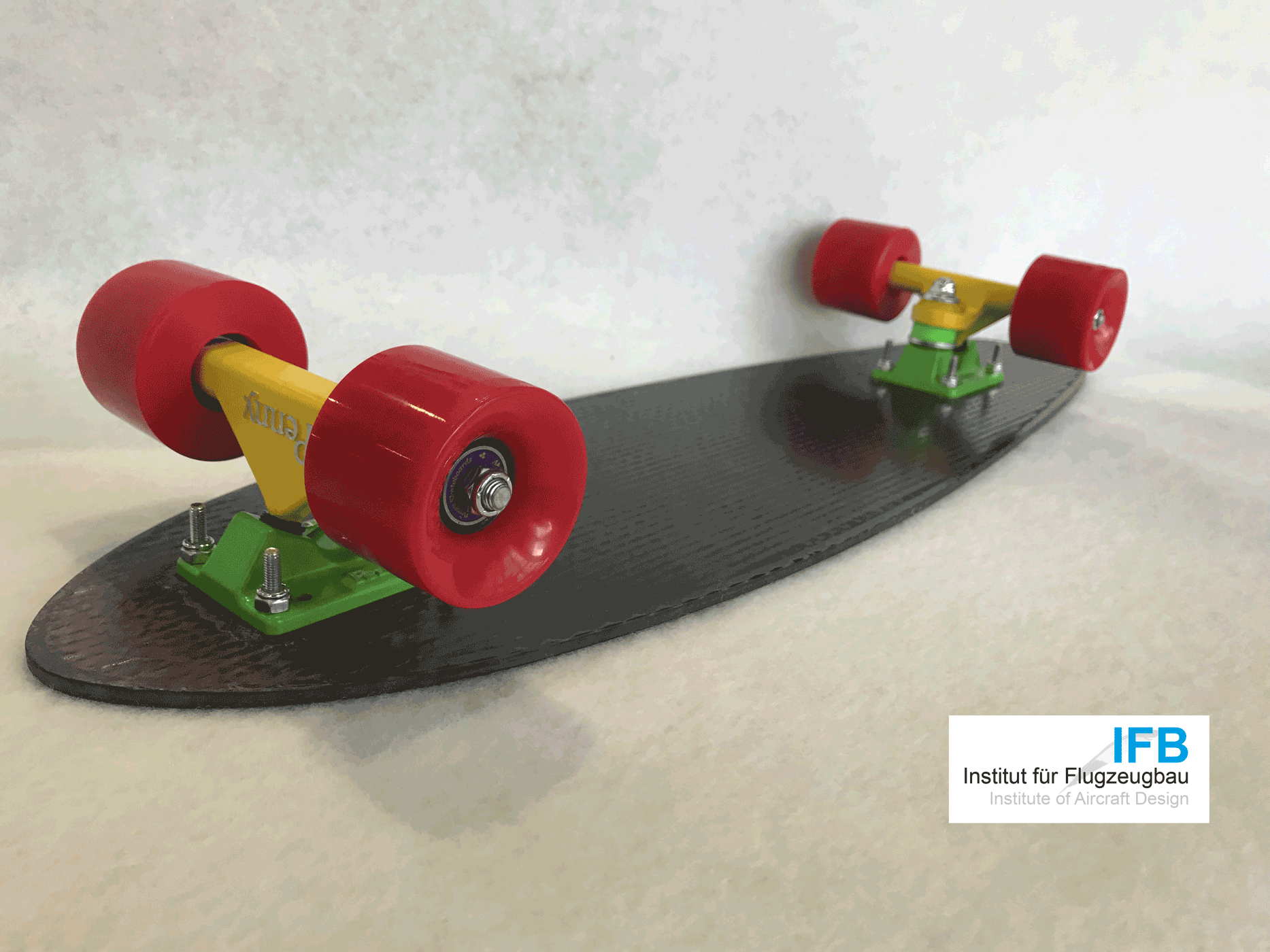

„Within the DFP (Dry Fibre Placement) process carbon fiber rovings are spread, bound and then auto-matically processed into dry textile preforms using 2D and 3D laying systems. The aim was to automate existing hand lay-up processes through simplicity and robustness, making it easy to use DFP technology. Process reliability, low waste and flexible production could be demonstrated. In this publication, influences of the process parameters, 2 mm wide gaps and the percentage of 90° layers in the laminate, are investigated with regard to the mechanical properties, permeability and infusion times in the preform z-direction (thickness). The influences on stiffness and strength, for tension and bending, are compared. Comprehensive unidirectional mechanical laminate properties were also determined for a reference configuration, without gaps, which can be used for computational laminate design. A method for determining infusion times as a function of laminate thickness, ply structure, 2 mm wide gaps is demonstrated and verified using vacuum assisted process (VAP) infusion tests.“

DRY FIBRE PLACEMENT – INFLUENCE OF PROCESS PARAMETERS ON MECHANICAL LAMINATE PROPERTIES AND INFUSION BEHAVIOUR

B. Grisin, S. Carosella und P. Middendorf

27. Stuttgarter Kunststoffkolloquium 2021